Properties

Control of standard components

| Temperature | 2 Pt100 sensors Class A in 4-wire-circuit, mutually monitoring and taking over the performance at the same temperature value |

|---|---|

| Controller | Electronic microprocessor temperature controller with auto-diagnostic system |

| Controller | digital display of all set parameters, such as temperature, weekdays, time, fan speed, programme status and set-up values |

| Timer | integrated timer for tempering profiles of up to 40 ramps each, each segment adjustable from 1 min. to 999 hrs. |

| Timer | digital 7-day programme timer with real time clock, precise minute setting, for one set value or start of ramp operation |

Temperature

| Set temperature range in °C | min.10°C above ambient up to +300°C |

|---|---|

| resolution of display for actual values | 0.1°C |

| resolution of display for setpoint values | 0.1°C up to 99.9°C, 0.5°C from 100°C |

| resolution of display/setting accuracy | 0.5°C up to 99.9°C, 1°C from 100°C |

Ventilation

| Fan | forced air circulation by quite air turbine, adjustable in 10 % steps for each segment individually |

|---|---|

| Fresh air admixture | adjustment of pre-heated fresh air admixture by air flap control in 10 % steps for each segment individually |

| Vent | vent connection with restrictor flap |

Communication

| Documentation | integrated ring memory as data logger for GLP-conforming long-term documentation of all relevant parameters - 1024 kB |

|---|---|

| Documentation | programme stored in case of power failure |

| Documentation | parallel printer interface (incl. real time clock with date function) for all PCL3-compatible ink jet printers for GLP-conforming documentation |

| Programming | multifunctional programming via menu on 8-digit alphanumeric digital display (language to be chosen via set-up): - tempering profiles of up to 40 ramps - time- and set-point dependent operation - speed of air turbine in 10 % steps |

Safety

| Temperature control | independently working, digitally adjustable electronic micro-processor overtemperature monitor TWW, protection class 3.1 (max-value for overtemperature, min-value for undertemperature) |

|---|---|

| Temperature control | mechanical temperature limiter TB, protection class 1 according to DIN 12880 to switch off the heating approx. 20°C above nominal temperature |

| AutoSAFETY | additionally integrated over- and undertemperature protection "ASF", automatically following the setpoint value at a preset tolerance range, alarm in case of over- or undertemperature, heating is switched off in case of overtemperature |

| Autodiagnostic system | for fault analysis |

| Alarm | visual and acoustic |

Standard equipment

| Door | fully insulated stainless steel doors on two sides |

|---|---|

| Interior | easy-to-clean interior,made of stainless steel,reinforced by deep drawn ribbing with integrated and protected large-area heating on four sides |

| Internals | 2 stainless steel grids |

| Installation | with feet |

Stainless steel interior

| Max. loading of chamber: | 300 kg |

|---|---|

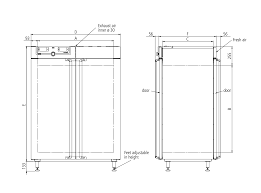

| Dimensions W x H x D in mm | w(A) x h(B) x d(C): 1040 x 1200 x 600 mm |

| Volume | 749 l |

Textured stainless steel casing

| pass-through version | |

|---|---|

| w(D) x h(E) x d(F): 1224 x 1726 x 784 mm |

Packing/shipping data

| the appliances must be transported upright | |

|---|---|

| Customs tariff number | 8419 8998 |

| Country of origin | Federal Republic of Germany |

| WEEE-Reg.-No. | DE 66812464 |

| Dimensions approx incl. carton | B x H x T: 1330 x 1920 x 1050 mm |

| Net weight | approx. 260 kg |

| Gross weight carton | approx. 331 kg |