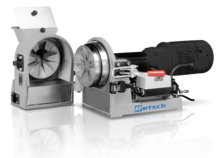

Product Advantages

- excellent crushing performance

- reproducible results due to accurate gap setting

- hinged grinding chamber for easy cleaning

- grinding discs with long working life

- wide range of materials for contamination free grinding

- connector for dust extraction

- can be operated together with Jaw Crusher BB 200

Features

| Applications | preliminary and fine grinding |

| Field of application | chemistry / plastics, construction materials, engineering / electronics, geology / metallurgy, glass / ceramics |

| Feed material | medium-hard, hard, brittle |

| Size reduction principle | pressure, friction |

| Material feed size* | < 20 mm |

| Final fineness* | < 100 µm |

| Speed at 50 Hz (60 Hz) | 440 min-1 (528 min-1) |

| Material of grinding tools | zirconium oxide, hardened steel, tungsten carbide, manganese steel |

| Gap width setting | continuous, 0.1 - 5 mm |

| Collector capacity | 2.5 l |

| Drive | 3-phase geared motor |

| Drive power | 1.5 kW |

| Electrical supply data | different voltages |

| Power connection | 3-phase |

| Protection code | IP 55 |

| W x H x D closed | 440 x 400 x 870 mm |

| Net weight | ~ 140 kg |

| Standards | CE |